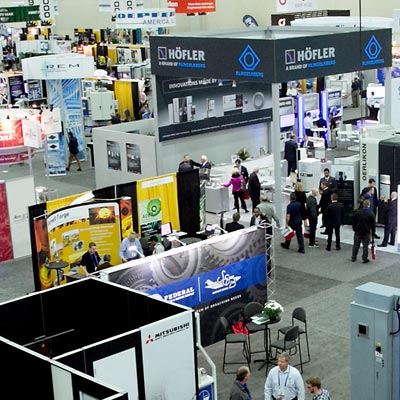

Accelerate innovation as we shape the future of motion and power at MPT Expo. It’s your one chance to see the latest technology, get expert insights and learn the trends that are shaping our industry.

The Motion + Power Technology Expo is three days of innovation, exploration, and learning. You will find advanced solutions in mechanical power transmission, fluid power, and electric drive – and with efficiency and power density at a premium – combining these technologies is often the key to success.

Why attend?

Cutting-Edge Solutions: Discover the latest advancements in gearing and power transmission technologies and compare products and services from over 300 exhibitors.

Unparalleled Networking: Connect with industry leaders, decision-makers, suppliers, and buyers from across the power transmission supply chain.

Expert Insights: Learn from industry leaders and gain valuable knowledge into the future of power transmission.

Find Solutions In

Mechanical

Power

- Gear Manufacturing

- Gearboxes

- Cutting Tools

- Housing and Shafts

Fluid

Power

- Hydraulic Fluid

- Control Valves

- Mobile Hydraulic Products

- Seals, Fittings, and Connections

Electrical

Power

- Battery Manufacturers

- Controllers

- eAxle

- Electric and Hybrid Drivetrains

Who Should Attend

If you are involved in the manufacturing of moving parts, then MPT Expo is a must-attend event. Discover the latest breakthroughs in mechanical, fluid power, electric, and hybrid technologies that are driving the power transmission supply chain forward.

No matter your industry – automotive, material handling, machine tool manufacturing, agriculture, automotive, off-highway, to construction or more – MPT Expo offers practical solutions to boost your operations. Connect with industry experts, explore advanced technologies, and gain a competitive edge.

Job functions include...

- Engineering

- Production Management

- Engineering Management

- Sales

- Purchasing

- VP-Level

- C-Suite

- Owners

- Presidents

- Consultants